Cast Bronze

Bronze CDA 67500

Specs: QQ-B-728, ASTM-B-138, ASTM-B-124

UNS# C67500

Manganese Bronze C67500 (Bronze CDA 67500) is strong, rigid and abrasion-resistant, has excellent hot working capacity as well as exceptional ratings for soldering and brazing. Its principal components are Copper and Zinc, with slight amounts of Lead, Tin, Iron, Aluminum, and Manganese.

This cast bronze alloy combines high strength with good corrosion resistance, making it ideal for automotive clutch discs, pump rods, balls, valve stems, and shafting.

Details

Alloy C67500 (CuZn37FeSnMn) is a wrought Manganese Bronze alloy with additions of iron, tin, and manganese to increase the strength and corrosion resistance.

The alloy can be cold worked to increase the strength and can be supplied in the half-hard and fully-hard condition.

It has excellent hot working properties and can be close die forged into valves, connectors, and other components for military applications. It can also be hot-headed or upset forged for manufacturing fasteners.

Manganese Bronze C67500 can be joined by soldering, brazing, and oxyacetylene welding and has a machinability rating of 30% compared with 100% for free machining brass.

The addition of tin aids its corrosion resistance in mild acidic waters.

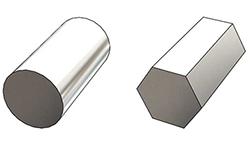

Available shapes – round and hex

Tools

Related Products

Applications

Industrial

- Clutch Discs

- Pump Rods

- Shafts

- Ball Valves

- Valve Stems

- Valve Bodies

- Fasteners

Get a quote for Bronze CDA 67500

Specifications

Specifications of Bronze CDA 67500

| International Standards |

Material Designation |

Rod, Bar & Profile |

Forgings |

|---|---|---|---|

| USA ASTM |

UNS C67500 Alloy A |

ASTM B 138 | ASTM B 124 ASTM B 283 |

| SAE | SAE J463 SAE J461 |

||

| Federal | QQ B 728 |

Mechanical Properties

Mechanical Properties of Bronze CDA 67500

| Product Form | Condition | Size Imperial Metric |

UTS Ksi N/mm² |

0.5% Yield Ksi N/mm² |

Elong % |

Hardness RB |

Shear Strength Ksi N/mm² |

|---|---|---|---|---|---|---|---|

| Rod & Bar | H02 Half Hard |

<=1” (<=25mm) | 72-77 500-530 | 36-45 50-310 | 13-23 | 83 | 47 325 |

| >1-2.5” (>25-65mm) | 70-72 450-495 | 35-42 240-290 | 15-27 | 77 | 44 305 | ||

| >2.5” (>65mm) | 65-70 450-485 | 32-35 220-240 | 17-30 | 70 |

Physical Properties

Physical Properties of Bronze CDA 67500

| Physical Properties | Imperial Units | Metric Units |

|---|---|---|

| Density | 0.302lb/in³ | 8.36g/cm³ |

| Melting Range | 1590-1630ºF | 865- 890ºc |

| Hot Working Range | 1157-1454 ºF | 625-790 ºc |

| Mean Liner Expansion 20-300ºc | 0.021 ºc x10-³ | |

| Mean Liner Expansion 68-572 ºF | 0.00118 ºF x10-³ | |

| Specific Heat | 0.090Btu/lb/ ºF @68ºF | 377J/kg ºK @20 ºc |

| Thermal Conductivity | 61Btu /ft²/fth ºF @68ºF | 105.6W/m. ºK |

| Electrical Conductivity | 24% IACS @68ºF | 0.14m/_mm² |

| Electrical Resistivity | 2.82µ_in | 7.2 μΩcm |

| Modulus of Elasticity 10³ | ||

| Tension | 15ksi | 103N/mm² |

| Rigidity | 5.6ksi | 39N/mm² |

While the data is believed to be accurate, Wieland Diversified makes no representation or warranty of any kind (expressed or implied) and assumes no responsibility with respect to the accuracy and values shown above; this information should only be used as a guide.

About Us

As part of the Wieland Group since 2018, Wieland Diversified will be able to continue to provide its customers with the quality and service they have come to expect. Learn more at Wieland.com

Contact Us

Wieland Diversified

49 Main Street

PO Box 65

Monson, MA 01057

p (800) 628-3035

p (413) 267-5101

f (413) 267-3151

Follow Us

Copyright 2021 © Wieland

All Rights Reserved. Privacy Policy