Naval Brass

Naval Brass C46400

Specs: ASTM-B-171, QQ-B-639, ASTM-B-21, ASTM B124, QQ-B-637, AMS 4611

UNS#: C46400

Naval Brass C46400 is an alloy that consists primarily of Copper and Zinc, with up to 1% Tin. Naval brass 46400 provides a high degree of corrosion resistance to seawater at even higher than normal temperatures, while also assuring greater strength and rigidity. It possesses excellent capacity for hot working and adapts well for hot forging and pressing. This Naval Brass also lends itself to drawing, forming, bending, and heading. It is readily soldered, brazed, and welded.

Wieland Diversifed maintains one of the most comprehensive stocking programs of Naval Brass in the country, which includes round bar and hexagon bar sizes.

Details

Naval Brass C46400 (CuZn39Sn1) is a 60/40 alpha beta brass with the addition of 1% tin, which aids the alloy to resist dezincification in seawater corrosion applications.

The tin also gives additional strength to the alloy without significantly reducing the ductility associated with 60/40 brass.

Naval Brass C46400 has excellent hot working characteristics that enable the alloy to be close die forged into valve bodies and other complex-shaped components and can be cold worked to increase the strength.

This enables the alloy to be supplied in the half-hard or fully hard condition.

Additionally, Naval Brass C46400 is used in the form of a flat product for condenser endplates in water treatment and desalination plants.

C46400 can be joined by soldering, brazing, and oxyacetylene welding, and has a machinability rating of 30% compared with free machining brass at 100%.

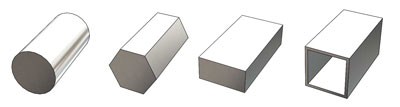

Available shapes – round, hex, rectangular and square

Tools

Related Products

Applications

Hardware

- Lock Pins

Electrical

- Precision Shipboard Equipment

Fasteners

- Bolts

- Nuts

- Rivets

Aerospace

- Landing Gear Bushings

- Aircraft Turn Buckle

- Barrels and Balls

Industrial Chemical/Oil/Water

- Valve Guides and Seats

- Bearings

- Bushings

- Pressure Vessels

- Valve Stems and Bodies

- Condenser Plates

- Hub Cones

- Welding Rod

- Structural Uses

- Heat Exchanger Plates

- Baffle plates

Automotive

- Valve Guides

- Valve Seats

- Marine

Decorative Fittings

- Turn Buckles

- Shafting

- Marine Hardware

Military

- Missile Components

Get a quote for Naval Brass C46400

Specifications

Specifications of Naval Brass C46400

| International Standards |

Material Designation |

Sheet & Plate | Strip | Rod, Bar & Profile |

Forgings |

|---|---|---|---|---|---|

| USA ASTM |

UNS C46400 | ASTM B 171 | ASTM B 171 | ASTM B 21 | ASTM B 124 |

| ASME | ASME SB 171 | ||||

| AMS | AMS 4611 AMS 4612 |

||||

| SAE | SAE J461 SAE J463 |

||||

| Federal | QQ-B-639 | QQ-B-639 | QQ B 639 QQ B 637 |

||

| Europe EN |

CuZn39Sn1 CW 719R |

EN 1653 | EN 12163 EN 12165 EN 12167 |

EN 12165 EN 12420 |

|

| Germany DIN |

CuZn39Sn1 Wk No. 2.0530 |

DIN 17670-1 DIN 17675-1 |

DIN 17660 | ||

| UK BS |

CZ 133 | BS 2874 | |||

| France NF A |

CuZn38Sn1 | NFA 51-115 | NFA 51-116 | NFA 51-116 | |

| Japan JIS |

C4640 C4641 |

JIS H 3100 | JIS H 3250 | ||

| Russia GOST |

L0601 | GOST 2060 GOST 6688 |

|||

| International ISO |

CuZn38Sn1 | ISO 1634-2 | ISO 1637 ISO 1639 |

Mechanical Properties

Mechanical Properties of Naval Brass C46400

| Product Form | Condition | Size Imperial Metric |

UTS Ksi N/mm² |

0.5% Yield N/mm² Ksi |

Elong % |

Hardness HB |

Shear Strength Ksi N/mm² |

|---|---|---|---|---|---|---|---|

| Rod & Bar | H02 Half Hard |

<=.5 (<=12mm) | 60-63 415-435 | 27-30 185-205 | 22-40 | 60-80 | 42 290 |

| Rod & Bar | H02 Half Hard |

>.5-1” (>12-25.4mm) | 60-63 415-435 | 27 -30 185-205 | 25-40 | 60-80 | 42 290 |

| Rod & Bar | H02 Half Hard |

>1-2” (>25.4-50 mm) | 58-62 400-425 | 26-28 180-195 | 25-43 | 55-80 | 42 290 |

| Rod & Bar | H02 Half Hard |

>2-3” (>50-75mm) | 54-57 370-395 | 25-27 170-180 | 25-43 | 55-80 | |

| Rod & Bar | H02 Half Hard |

>3-4” (>75-100mm) | 54-57 370-395 | 22-24 150-165 | 27-45 | 55-80 | |

| Rod & Bar | H02 Half Hard |

>4” (>100mm) | 54-57 370-395 | 22-24 150-165 | 30-48 | 55-80 |

Physical Properties

Physical Properties of Naval Brass C46400

| Physical Properties | Imperial Units | Metric Units |

|---|---|---|

| Density | 0.304lb/in³ | 8.41g/cm³ |

| Melting Range | 1630-1650ºF | 865-890ºc |

| Hot Working Range | 1202-1500 ºF | 650-815 ºc |

| Mean Liner Expansion 20-300ºc | 0.021 ºc x10-³ | |

| Mean Liner Expansion 68-572 ºF | 0.00118 ºF x10-³ | |

| Specific Heat | 0..090Btu/lb/ ºF @68ºF | 377J/kg ºK @20 ºc |

| Magnetic Permeability | <1.01 | |

| Thermal Conductivity | 67Btu /ft²/fth ºF @68ºF | 116W/m. ºK |

| Electrical Resistivity | 2.61µ_in | 6.63 μΩcm |

| Electrical Conductivity | 26% IACS @68ºF | 0.152MS/cm@20 ºc |

| Modulus of Elasticity 10³ | ||

| Modulus of Rigidity | 6.4ksi | 44.13N/mm² |

| Tension | 15ksi | 103N/mm² |

| Rigidity | 5.6ksi | 39 N/mm² |

While the data is believed to be accurate, Diversified Metals, Inc. makes no representation or warranty of any kind (expressed or implied) and assumes no responsibility with respect to the accuracy and values shown above; this information should only be used as a guide.

About Us

As part of the Wieland Group since 2018, Wieland Diversified will be able to continue to provide its customers with the quality and service they have come to expect. Learn more at Wieland.com

Contact Us

Wieland Diversified

49 Main Street

PO Box 65

Monson, MA 01057

p (800) 628-3035

p (413) 267-5101

f (413) 267-3151

Follow Us

Copyright 2021 © Wieland

All Rights Reserved. Privacy Policy