HY 80 / 100 Steels

HY 100 Steel

Specs: MIL-S-21952 T9074-BD-GIB-010/0300

UNS#: K32045

HY 100 is a high yield steel with minimum yield strength of 100 ksi. While many steels offer high yield strength, HY 100 also offers exceptionally high impact strength as well. This combination makes HY 100 unique among steels. This material is used extensively in marine defense and petrochemical applications.

Wieland Diversified is the largest stocking distributor of HY 80 and HY 100 in NorthAmerica; stocking a full line of round stock, while also offering gun drilled tubing.

Certified to the MIL-S-21952 C/D and T9074-BD-GIB-010/0300

HY is also available in ID/OD Tubing up to 22′ length. Contact us with your requirements.

Details

Heat Analysis

- HY 100 was used in the construction of the Seawolf Class nuclear powered fast attack submarines where the design dictated that the craft had to operate at greater depths than previous designs and hence withstand increased hull pressure.

- In addition, the alloy had to have a high degree of toughness and impact strength to withstand the massive changes in pressure and has excellent fabrication properties to allow the welding of complex structures.

- The alloy has high strength, a minimum of 100ksi proof stress, which is obtained by a water quench and aging heat treatment.

- This low alloy martensitic steel contains small additions of chromium and nickel to help with corrosion resistance and is supplied in the Type B condition bright finish.

- Owing to the rigorous requirements of the end application, all material is electric arc melted and vacuumed degassed with argon. All bar stock is ultrasonically tested to MIL STD 271,(NAVSEA T9074-AS-GIB-010/271) and has full Level I Subsea traceability.

- Wieland Diversified also has the capabilities of supplying gun-drilled tubing.

- The alloy has since found wider applications in the construction of pressure vessels, armor plating, the petrochemical industry, and many other applications requiring greater strength and high integrity material.

Welding

- Weldments of HY-80 are noted for good ductility, notch toughness, and strength. It is recommended to weld using the metal-arc process with low hydrogen electrodes of Type E-10018 or E-11018. It is important to use approved weld procedures, so that the correct heat input per inch of weld bead is introduced, which would otherwise cause degradation of notch toughness. Electrodes should be warmed before use to drive off any moisture to avoid hydrogen pick-up in the weld. Preheating is not required, except for very heavy section thickness welds or heavily constrained welds. Post-heating is not required but a stress relief anneal, after welding of sections of 1-1/2″ thick or greater, is desirable. However, the alloy may be used in the as-welded condition.

Tubing

- High-pressure tubing can be made from HY 100 and HY 80 bars up to 30 feet in length. Tubes can be welded together to achieve longer lengths. The material’s superior combination of ductility and fracture toughness makes it a great choice for pressures as high as 14,000 PSIG operating pressure or more depending on wall thickness. The tubes have been tested up to 21,000 PSGI. Typical operating temperatures are 500o F to -20o F. The tubes can be bent up to 180 degrees with a maximum allowable thinning of 10% and flattening of 8% depending on tube OD and wall thickness and will maintain their physical properties. ID surface finishes of 64 micro or greater can be achieved. Straightness tolerances of .015″ per foot can be maintained. Bars can be ultrasonically tested in immersion and/or Mag Particle tested to ensure integrity after drilling.

Fracture Toughness

- High Strength HY100 steel has a well-documented history in pressure vessel applications, particularly in Submarine hull construction.

- Under arduous working conditions the steel has to have excellent low cycle fatigue properties and in conjunction with high resistance to crack propagation.

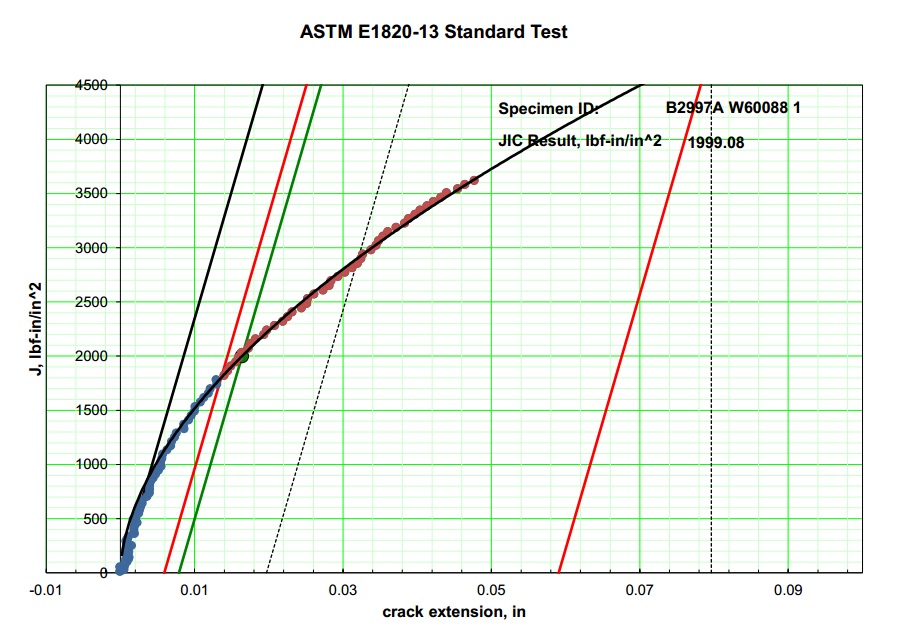

- Recent work conducted by Wieland Diversified on 3.5” solid bar stock has confirmed the excellent fracture toughness properties of HY 100

- Tests were performed to ASTM E 1820 C(T) geometry and C-R orientation at a temperature of 73ºc in air.

Typical graph:

Initiation toughness values J1c ranged from 1341-1999 lbf-in/in

With Fracture toughness KJ1c values ranging from 210-257 ksi√2

These were taken from bars with a range of mechanical properties

| Proof Stress | UTS | Modulus |

|---|---|---|

| ksi | ksi | Msi |

| 111-115 | 125 -129 | 30 |

Available Shapes – round

Related Products

Applications

HY 100 Steel Applications

- Pressure vessels

- Submarine construction

- Naval Craft construction

- Heavy construction equipment

- Armor plate for vehicles

- Bank trucks

- Guard Booths and barriers

- Storage tanks for liquefied hydrocarbon vapors

- Petrochemical

- Helicopter hold down rasters

Get a quote for HY 100 Steel

Chemical Composition

Chemical Composition

| C | Mn | P | S | Si | Cr | Ni | Mo | V | Ti | Cu | Sb | As | Sn | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | 0.10 | 0.10 | – | – | 0.15 | 1.35 | 2.75 | 0.30 | – | – | – | – | – | – | Bal |

| Max | 0.20 | 0.40 | 0.015 | 0.004 | 0.35 | 1.8 | 3.50 | 0.60 | 0.03 | 0.02 | 0.25 | 0.025 | 0.025 | 0.03 |

Specifications

Specifications of HY 100 Steel

| International Standards |

Material Designation |

Tube & Pipe Seamless |

Sheet & Plate | Rod & Bar | Forgings Stampings |

|---|---|---|---|---|---|

| USA Military |

UNS K31820 | MIL-S-16216 Rev K MIL-S-24645 Rev A MIL-S-24371 Rev B |

MIL-S- 21952 Rev C & D MIL-S-22664 Rev B |

MIL-S -24512 MIL-S-23009 Rev C |

|

| Naval | EB 3719 Rev C EB 2678 Rev H EB 3132 Rev D T9074-BD-GIB-010/0300 T9074-BD-GIB-010/271 |

||||

| ASTM | A543 Grade B&C | ||||

| United Kingdom Military |

DEF STAN 02-736 Part 1 |

DEF STAN 02-736 Part 4 |

DEF STAN 02-736 Part 2 |

Mechanical Properties

Mechanical Properties of HY 100 Steel

| Ultimate Tensile Strength* | 0.2% Yield Strength | Elong in 2″ (Min) | Reduction of Area (Min) | Hardness |

|---|---|---|---|---|

| Ksi N/mm² | Ksi N/mm² | % | % | BHN |

| 115-135 792-930 | 100-120 690-897 | 18 (L) 16 (T) | 50 (L) 45 (T) | 230-290 |

* Not a requirement of the specification

(L) longtitudinal

(T) transverse

Impact Properties

Impact Properties of HY 100 Steel

| Test Temperature | Charpy V-notch Longitudinal | Charpy V-notch Transverse** |

|---|---|---|

| °F °c | ft lbs Joules | ft lbs Joules |

| -120 -84 | 50 68 | 50 68 |

| 0 -18 | 70 95 | 60 81 |

**Transverse properties only required for 4″ (100mm) dia or greater

The properties shown below are for guidance only and are not intended for specification purposes.

Physical Properties

Physical Properties of HY 80 Steel

Physical Properties of HY 100 Steel

| Physical Properties | Imperial Units | Metric Units |

|---|---|---|

| Density | 0.28 lb/in³ | 7.83 /cm³ |

| Melting Range | 2640-2750ºF | 1450-1510ºc |

| Mean Liner Expansion 0-200ºc | 18_m/m.ºc | |

| Mean Liner Expansion 0-400 ºF | 0.010 in/in/ ºF x10³ | |

| Specific Heat | 0.11Btu/lb/ ºF | 460J/kg ºc |

| Poisson€s ratio | 0.28 | 0.28 |

| Thermal Conductivity | 48.18Btu-in/sec/ft²/ ºF | 25W/m. ºk |

| Modulus of Elasticity 10³ | 29ksi | 200 N/mm² |

| Shear Modulus 10³ | 11.2ksi | 77 N/mm² |

The data is believed to be accurate but Diversified Metals Inc makes no representation or warranty of any kind (expressed or implied) and assumes no responsibility with respect to its accuracy and values should only be used as a guide.

About Us

As part of the Wieland Group since 2018, Wieland Diversified will be able to continue to provide its customers with the quality and service they have come to expect. Learn more at Wieland.com

Contact Us

Wieland Diversified

49 Main Street

PO Box 65

Monson, MA 01057

p (800) 628-3035

p (413) 267-5101

f (413) 267-3151

Follow Us

Copyright 2021 © Wieland

All Rights Reserved. Privacy Policy